Electrode Material CuCo2Be – CuCo2Be DIN EN 12163/12167

Electrode Material CuCo2Be is a high strength electrode material which, by way of special heat treatment, combines high hardness with good thermal and electrical conductivity. Heating beyond the softening temperature of 500°C significantly reduces the mechanical and physical values.

Chemical composition (DIN EN 12163:2016-11)

Element Cu Co Be Ni* Fe*

Min. [%] - 2 0,4 - -

Max. [%] Rest 2,8 0,7 0,3 0,2

Mechanical properties (Guideline values)

Round bars Ø 10 - 35 mm Ø 40 - 80 mm

Yield point Rp0,2 [N/mm2] ≥ 650 ≥ 550

Tensile strength Rm [N/mm2] ≥ 700 ≥ 700

Brinell hardness [HB] ≥ 240 ≥ 220

Elongation at fracture A [%] ≥ 10 ≥ 15

Modulus of elasticity E [kN/mm2] ~ 120 ~ 120

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 17 Electrical conductivity [m/Wmm2] 26

Thermal conductivity [W/mK] 196 Specific gravity [kg/dm3] 8,8

Standards

DIN EN 12163/12167 CuCo2Be ASTM Alloy C 17500

DIN 17666/17672 CuCo2Be AFNOR UK 2 Be

Material designation

DIN EN 12163 DIN 17666

Abbreviated designation Number Abbreviated designation Number

CuCo2Be CW104C CuCo2Be 2.1285

Forms of delivery

Range [mm] Tolerance [mm] Manufacturing method

Round bars Ø 10 - 20 0/- 0,2 drawn

Round bars > Ø 20 0/+1 pressed

Example uses

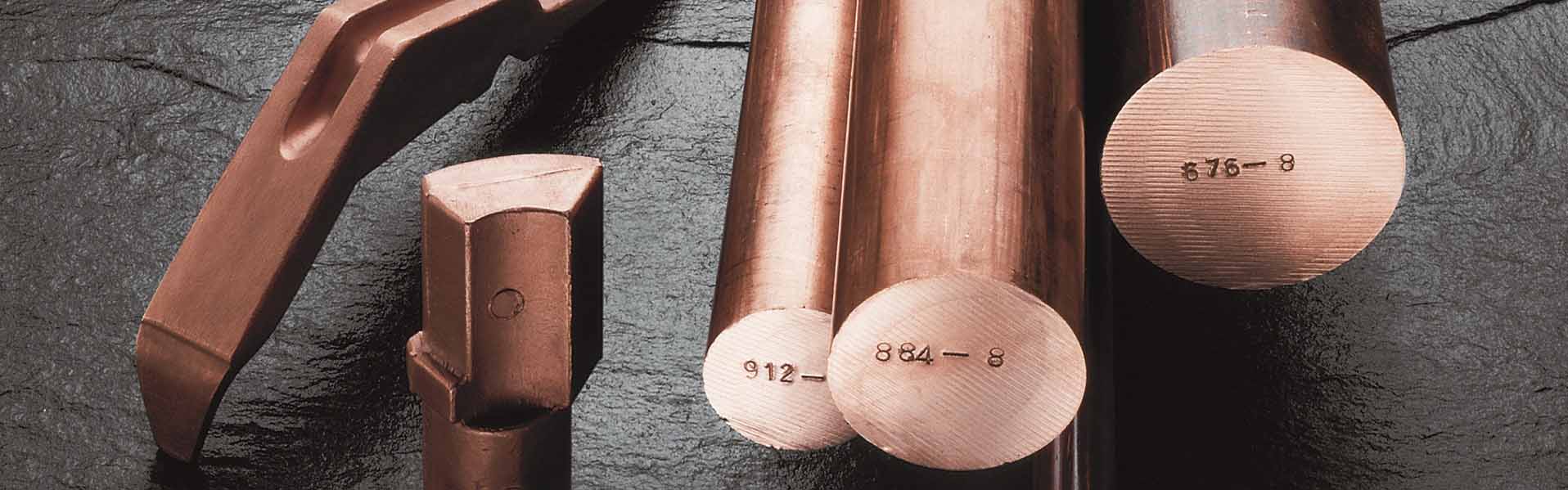

Electrodes for electrical resistance welding (spot, roll seam, projection and butt welding). Electrode Material CuCo2Be is primarily used to weld alloyed, high strength, corrosion-resistant steels.

Machinability

Electrode Material CuCo2Be is machinable similar to pure copper. The formation of built-up edges can be counteracted by increasing the cutting speed.

Electrode Material CuCo2Be – Availability

- Round bars from Ø 10-105 mm are available from stock.

- We also supply rectangular and flat bars by arrangement.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.