Wieland-B09

Wieland-B09 rolled bushings are made of wrought material CuSn8 and, despite their thin-walled construction, can withstand very high loads. Hence these bearings are predestined for swing bearings (oscillating motion), the most common use for rolled Wieland bushings.

The excellent tin bronze material gives the bushings excellent sliding properties and high wear resistance.

Wieland rolled bushings are used, on the one hand, in standardised dimensions with lubrication pockets. The advantage of this type of bushing is that it can be shortened to any desired length.

We also offer special designs and sizes according to your specifications.

Wieland-B09 – Material description

A tin bronze with excellent sliding properties. The material is particularly suitable when high wear resistance, corrosion resistance and fatigue strength are required.

Due to the thin-walled construction of rolled bushings, they can absorb very high specific forces. These may be higher than for the relatively thick-walled turned bushings. Very high loads are possible, especially with swing bearings (oscillating motion).

Material designation: CuSn8P DIN ISO 4382-2 Composition (Guideline values mass fraction): Cu 91,3%, Sn 8,5%, P 0,2%

Table of contents

> Wieland-B09 – Material description

> Physical properties

> Strength properties

> Allowable loading capacity of bearings

> General properties

> Instructions for use

> Dimensional tolerances

> Installation tolerances

> Bearings with lubrication indents

> Bearings with hole pattern

> Bearings with seals

> Shaft materials and surface quality

> Lubrication

> Lubricants

> Bearing clearance and shaft tolerance

> Design notes

> Installation and lubrication of bearings with seals

> Links

Physical properties (Guideline values)

Specific gravity: 8,8 kg/dm3 Coefficient of thermal expansion (20 – 300°C): 18,5 10-6/K

Thermal conductivity: 60 W/mK Modulus of elasticity (20°C): 115 kN/mm2

Strength properties (Guideline values)

Hardness: 125 HB Tensile strength Rm; 470 N/mm2

0,2%-Yield point Rpp0,2: 300 N/mm2 Elongation at fracture A: 40 %

Allowable loading capacity of bearings

Guideline value for allowable loading capacity of the bearing materials with hardened shafts, swing bearings (oscillating motion) or speeds up to v = ~ 0.01 m/s as well as grease lubrication: 120 N/mm2

Rotating shaft > 2 m/s: 40 N/mm2

General properties

The characteristic feature of rolled bushings is their thin-walled construction. Therefore, the space required for bearings with the same shaft diameter and the same stress parameters is smaller than for turned bushings or even rolling bearings. This is all the more significant for larger shaft diameters. Rolled bushings can be supplied with or without flange.

Advantages:

- fully recyclable

- cheaper than machined bearings

- minimal space requirement

- weight reduction compared with machined bearings or rolling bearings

- high load capacity, therefore particularly suitable for swing bearings

- grooves are stamped

- grease deposits for long-term lubrication possible

Instructions for use

High load capacity bronze with very good thermal stability, very good corrosion resistance, wear resistant. Hardened shafts are necessary at high loads.

Use: Spherical plain bearings under shock and impact loads, bearings in hydraulic cylinders, bearings in the jibs of excavator joints and in agricultural machinery.

For flanged bushings:

- radial and axial forces are absorbed by a bushing

- instead of thrust washer and cylindrical bushing, only one bearing element

- high dimensional stability; fixing operation omitted, e.g. for thrust washers

Dimensional tolerances

Cylindrical bearings with lubrication indents ST

Cylindrical bearings with hole pattern LD

Cylindrical bearings with seals LDD

Outside and inside chamfering

| s* | f1 | f2 |

| 1 | 0,6 ± 0,4 | max. 0,4** |

| 1,5 | 0,6 ± 0,4 | 0,4 ± 0,3** |

| 2 | 1,2 ± 0,4 | 0,4 ± 0,3 |

| 2,5 | 1,8 ± 0,6 | 0,6 ± 0,4 |

* s = b2 = (d2 – d1) / 2

** optional rounded corners

Flanged bearings with lubrication indents ST

Flanged bearings with hole pattern LD

Installation tolerances

Nominal dimension d1 Installation tolerance

bigger than till Housing H7 Bearing inside-Ø after mounting into housing H7 (middle)

10 18 0 / +0,018 0 / +0,043

18 30 0 / +0,021 0 / +0,052

30 50 0 / +0,025 0 / +0,062

50 80 0 / +0,030 0 / +0,074

80 120 0 / +0,035 0 / +0,087

120 180 0 / +0,040 0 / +0,100

180 250 0 / +0,046 0 / +0,115

250 305 0 / +0,052 0 / +0,130

Check according to DIN 1494/ISO 3547 part 2

Flange diameter [d3] is defined in accordance with DIN ISO 2768 with rough

Width tolerance for cylindrical and flanged bearings

Width [b1] till outside diameters [d2] 100 mm: ±0,25 mm

Width [b1] bigger than outside diameters [d2] 100 mm: ±0,5 mm

Bearings with lubrication indents

Bushings with lubrication indents are sliding elements that have proven their worth for many years. The lubrication indents, which are already integrated into the bands, are evenly distributed over the entire running surface. Filled with grease before mounting the shaft, they help to provide a uniform film of grease over the entire bearing.

An advantage of the bushings with lubrication indents is that they can be shortened to any desired width without creating a disadvantage for the lubrication indents.

Lubrication indent N° 3 – contact ratio contact ratio 75%

Rhombus-shaped for bearings Ø ≤ 16 mm,

DIN 1494/ISO 3547, part 3, type N2

Lubrication indent N° 4 – contact ratio contact ratio 78%

Rhombus-shaped for bearings Ø > 16 mm,

DIN 1494/ISO 3547, part 3, type N2

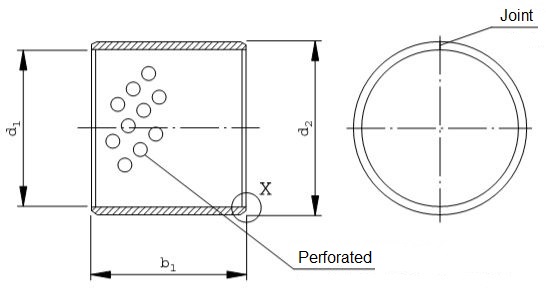

Bearings with hole pattern

The perforated bushings are a further development of the bushings with lubrication pockets. They are provided with a precisely defined hole pattern, which when filled with grease or paste has the following advantages:

- the running time is extended

- the lubrication interval is increased

- dirt and abrasion are collected in the holes and

- the wear behaviour is significantly improved

For these bushings

- grease or paste can be selected individually

- the bearing conditions can be adapted individually and

- the bearing material can be recycled

A shortening of the standard bushings to intermediate widths is only partly recommended, since the holes are cut and this results in sharp edges. Bushings with different widths should therefore be newly manufactured.

Bearings with seals

As opposed to the known plain bearing designs, in which bushing and seal have to be installed separately, it is also possible to obtain bushing and seal as a complete part.

The bearing with seal has the following advantages:

- the running time is significantly extended:

– optimal lubrication as the bearing is filled first before the grease escapes through the seal

– protection against moisture ingress and foreign bodies of all kinds - minimum space requirements compared to the usual seals

- seals and plain bearings 100% recyclable

- only one complete part is ordered and assembled, no different parts – and storage is simplified

Properties of the seal:

- very good flexibility over a wide temperature range in combination with maximum sealing effect with high abrasion resistance

- no shrinkage of the sealing lip in the shaft

- linear support even under load and edge pressure

- excellent resistance to greases, oils and hydraulic fluids

- high resistance to UV light and aging of the material

Shaft materials and surface quality

The surface hardness of the shafts should preferably be greater than 50 HRC. Therefore, alloyed steels or steels with appropriate surface treatment are especially recommended. Hard chrome plated shafts are also well proven; however, the chrome layer should be kept as thin as possible.

The shafts should be ground to Rz values between 1 and 4 μm. If these roughness values cannot be achieved, additional polishing or “stripping” of the shaft is recommended to break the roughness peaks and increase the contact area. Drawn shafts have also proven their worth, especially for axial movements.

Lubrication

It is not only the bushing and shaft that are important in the tribological system; lubrication and the ambient medium (e.g. air, gas, salt water, dust, etc.) are equally important. The ambient medium is often not controllable, unlike the lubrication.

Lubrication not only improves the sliding properties; further advantages are also achieved:

- long service life

- corrosion protection of shaft

- seal against dust and dirt

- low friction losses

Friction is caused by the interaction of two bodies under load and movement. To reduce friction and wear, the lubricant performs an extremely important function: it separates the metallic surfaces of the bushing and shaft.

Lubricants

- lithium saponified grease for standard bearings

- lithium saponified grease with additives for higher demands

- pastes for long term lubrication

- oil in closed systems

Bearing clearance and shaft tolerance

Situation: Bearing clearance:

Lubrication condition: grease >0,1 mm

Lubrication condition: oil small

Load: big small

Load: small big

Movement: slow small

Movement: oscillating small

Movement: fast big

The required middle bearing clearance depend on the provided lubrication, the load und the sliding speed.

The chart is intended to facilitate the choice of the necessary clearance. The curve is designed for general mechanical engineering. For bearings in rough operation, the curve can be exceeded slightly in the upward direction.

The tolerance of the shaft must be set according to the desired minimum clearance. The tolerance class should be IT6 for high requirements and IT7 or IT8 in normal cases.

If standard bushings with inside diameter tolerance H9 are used, it is recommended to tolerate the shaft with e or f. For shafts with h tolerance, provided that the bearing load is not too high the housing bore can be extended from H7 to F7. The bushing attaches to the respective housing and the bushing bore is slightly larger. This means that bearing clearances that are too small can be avoided.

Design notes

Housing and bearing

The locating hole in the housing should preferably be designed with tolerance H7. In the standard version, after insertion into this hole the inner diameter of the bushing usually has the tolerance H9. If other tolerances are required, please enquire.

When not installed, rolled bushings can easily rebound at the butt joint; however, this does not affect the mass or the tightness of the fit when installed. Like turned bushings, the bushings have a press fit allowance. When pressing in the bushing, the joint closes and the butt joint surfaces fit snugly together, so that the press fit allowance can act. The bushing adapts to the housing and thereby obtains its final shape. To facilitate the installation of the bushing, the housing should have a chamfer between 15° and 45° (flange bushings 45°). For flange bushings, care must also be taken to ensure that the chamfering in the housing is matched to the radius between the bushing shaft and the flange. The radius R corresponds to the bushing wall thickness, min. 2 mm.

Shoulder mandrel

Bearing

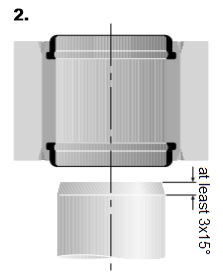

Installation and lubrication of bearings with seals

1. Pressing in the bearing

The bushing is pressed in with mounted seals. A shoulder mandrel with free rotation for the sealing lip between the guide shaft and the shoulder is recommended to ensure error-free installation. Free rotation is necessary so that the seal is not damaged during pressing. The shoulder mandrel should have a leadin chamfer of at least 3 mm x 15°.

However, the bushing can also be pressed in with a plate. Here, the seal is pressed elastically towards the middle of the bushing and goes back to its original position after the press-fitting process.

2. Mounting the shaft

When mounting the shaft, it must be taken into account that the inner diameter of the sealing lip has a smaller diameter than the shaft. Therefore, to allow easy insertion the shaft should have a chamfer of at least 3 mm x 15°. Mounting is further simplified if the shaft is lightly greased before insertion.

3. Lubricating the bearing

Without a seal, complete filling of the bearing via the grease nipple is not guaranteed. In the unstressed area, grease quickly leaks out, whereas the stressed area remains unfilled. The seal causes throttle pressure to be built up in the bearing during lubrication, whereby only after complete filling of the bushing does the grease escape through the seal. If the bushing cannot be lubricated via a grease nipple, make sure the bushing is well lubricated before mounting the shaft.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.