Lobrodur 18 (LBD 18) – CuNi2Si DIN EN 12163/12167

Lobrodur 18 is a CuNiSi-based curable copper alloy. It is characterised in particular by excellent cold and hot formability, exceptional corrosion resistance, high strength and hardness achievable through tempering (hardening), good sliding properties, wear resistance, insensitivity to stress corrosion, resistance to weather conditions and good electrical conductivity.

The high strength, yield strength and hardness of this product is achieved through a combination of cold work hardening and thermal hardening. As a result, the mechanical properties are highly heat resistant.

These outstanding properties, in particular the heat treatability and the fact that hardening can be carried out without difficulty at the end of the machining process, allow versatile applications in the fields of electrical engineering, plain bearing technology, chemical plant engineering and general mechanical engineering.

Chemical composition (DIN EN 12163:2016-11)

Element Cu Ni Si Fe* Mn* Pb*

Min. [%] - 1,6 0,4 - - -

Max. [%] Rest 2,5 0,8 0,2 0,1 0,02

Mechanical properties (Guideline values)

Round bars* Ø 10–40 mm Ø 45–61 mm Ø 71–110 mm

Yield point Rp0,2 [N/mm2] ≥ 590 ≥ 550 ≥ 520

Tensile strength Rm [N/mm2] ≥ 640 ≥ 620 ≥ 590

Brinell hardness [HB] ≥ 180 ≥ 180 ≥ 180

Elongation at fracture A [%] ≥ 10 ≥ 10 ≥ 10

Modulus of elasticity E [kN/mm2] ~ 130 ~ 130 ~ 130

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 17 Electrical conductivity [m/Wmm2] 17

Thermal conductivity [W/mK] 160 Specific gravity [kg/dm3] 8,8

Standards

DIN EN 12163/12167 CuNi2Si DIN 17666/17672 CuNi2Si

Material designation

DIN EN 12163 DIN 17666

Abbreviated designation Number Abbreviated designation Number

CuNi2Si CW111C CuNi2Si 2.0855

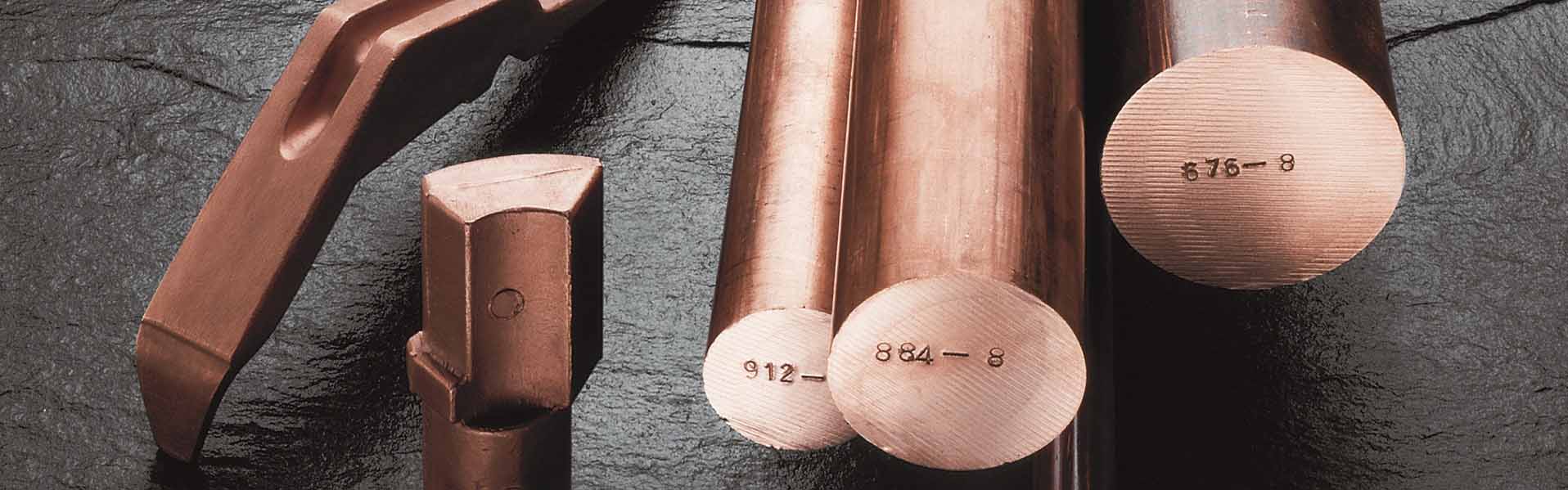

Forms of delivery

Range [mm] Tolerance [mm] Manufacturing method

Round bars Ø 10 - 56 h11 drawn

Round bars Ø 61 - 122 0/+1 pressed

Example uses

Lobrodur 18 is particularly suitable for bearing bushings, valve guide and guide bushings, guide rails, sliding elements, including those for vibrating and oscillating movements, heat-stressed bearings, high strength screws, electrical contact elements subject to wear, relay screws, drop forged parts, catenary clamps, etc.

Machinability

This material offers good cold formability and excellent hot formability. For hot forming, delivery in the pressed form is recommended.

The processing temperature is approximately 880-900°C.

Lobrodur 18 is best machined in the hardened condition. If the parts are to be mechanically processed after forming, it is expedient to carry out thermal hardening after forming and before machining.

The mechanical properties and electrical conductivity increase during hardening. As our stored round bars are already hardened, the parts should not be subject to any further heat treatment.

Lobrodur 18 – Availability

- Cold drawn and hardened round bars from Ø 10–102 mm are available from stock.

- Round bars from Ø 102–122 mm are available at short notice.

- Flat and hexagonal bars are also available at short notice.

- Depending on the use can Lobrodur 18 also “suitable for thermosetting” may be delivered.

- Ready-to-install parts in accordance with customer drawing.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.