Looser Special Brass 27 (LSM 27) – CuZn25Al5Mn4Fe3-C-GS/GZ/GM DIN EN 1982

Looser Special Brass 27 is a multi-material alloy with high manganese and aluminium content. It is a construction material with very high static load capacity, particularly high yield strength and tensile strength. It is not suitable for dynamic loads and vibrations.

Can be used up to temperatures of max. 150°C.

Chemical composition (DIN EN 1982:2017-11)

Element Cu* Zn Al Mn Fe Ni Pb Sn Si P Sb

Min. [%] 60 - 3 2,5 1,5 - - - - - -

Max. [%] 67 Rest 7 5 4 3 0,2 0,2 0,1 0,03 0,03

* inclusive Ni

Mechanical properties (DIN EN 1982:2017-11)

Centrifugal casting-GZ

Yield point Rp0,2 [N/mm2] ≥ 480

Tensile strength Rm [N/mm2] ≥ 750

Brinell hardness [HB] ≥ 190

Elongation at fracture A [%] ≥ 5

Bending fatigue strength* Rbw [N/mm2] ± 150

Modulus of elasticity** E [kN/mm2] ≥ 105

* Guideline value with 108 load cycles and at 20°C / ** Guideline value

The sample bar is removed from the casting in the case of centrifugal castings and continuous castings. The sample position – e.g. lengthwise or crosswise sample – must be agreed between orderer and manufacturer: the values specified in the table apply only to wall thicknesses up to 50 mm for the blank casting. In the case of wall thicknesses over 50 mm, with the wall thickness of the blank casting being the decisive factor, it must be anticipated that the strength and hardness values are lower. This applies in particular to the yield point.

It must not be expected that the strength and hardness values are uniformly high at all points of the casting. In general, the values in the outer layers will be higher than in the core zone.

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 18 Electrical conductivity [m/Wmm2] 7,5

Thermal conductivity [W/mK] 50 Specific gravity [kg/dm3] 8,2

Standards

DIN EN 1982 CuZn25Al5Mn4Fe3-C-GS/GZ/GM DIN 1709 G/GZ/GK-CuZn25Al5 (G-SoMs F75)

Material designation

DIN EN 1982 DIN 1709

Abbreviated designation Number Casting method Abbreviated designation Number

CuZn25Al5Mn4Fe3-C-GS CC762S-GS GS or G G-CuZn25Al5 2.0598.01

CuZn25Al5Mn4Fe3-C-GM CC762S-GM GM or GK GK-CuZn25Al5 2.0598.02

CuZn25Al5Mn4Fe3-C-GZ CC762S-GZ GZ GZ-CuZn25Al5 2.0598.03

GS = G = Sand casting, GM = GK = Permanent mold casting, GZ = Centrifugal casting

Example uses

- Used in the same way as Looser Special Brass 24, but for even higher pressures.

- Structural parts with very heavy static loads, e.g. bearings with very low sliding speeds and very high loads, such as thrust bearing rings and bridge bearings, internal parts and spindles for heavy duty high pressure fittings, swivel blocks in rolling mills, pressure shells for block and slab cutters.

- Permissible static surface pressure [p] of max. 240 N/mm2.

- Looser Special Brass 27 is well suited for worm wheel rims with maximum load and low sliding speeds (vmax 4 m/s with low duty cycle).

Machinability

Moderately difficult to machine, difficult to weld, not suitable for soldering.

Sliding partners

For sliding, the mating material must be hardened and finely ground. Reliable lubrication is required in all cases.

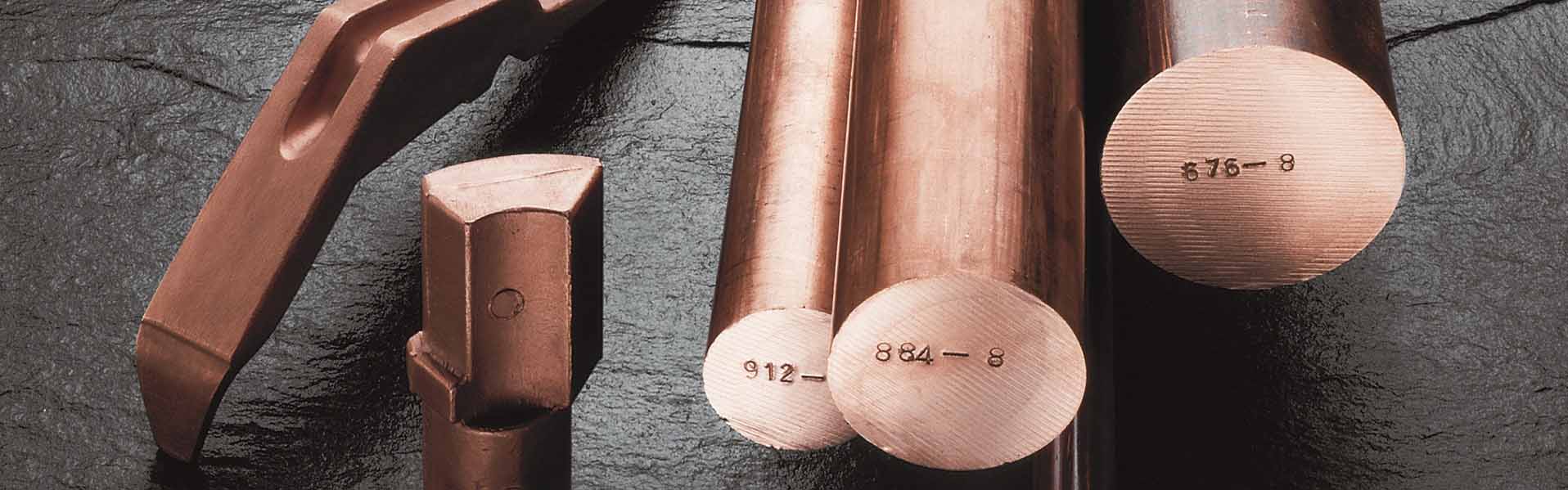

Looser Special Brass 27 – Availability

Centrifuged rings and bushings pre-turned to the rough sizes or contour.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.

Links

Additional information can be found in this Looser Bronzes catalogue or under download.