Looser Bronze 66 (LB 66) – CuSn11Pb2-C-GS/GC/GZ DIN EN 1982

Looser Bronze 66 is a tin bronze with added lead. It is tough, resistant to wear, corrosion and seawater, has good emergency running properties and is impact-resistant.

Example uses

This material has proven to be excellent for highly stressed plain bearings, e.g. grinding machine spindle bearings, main spindle bearings for fine finishing machines, flywheel bearings for presses, piston pin bushings, bearings for crane wheels, highly stressed toggle, connecting rod and crank bearings for forging machines and eccentric presses. Highly stressed sliding plates and strips. Although Looser Bronze 66 is a noted bearing material, it is also used successfully for spindle nuts that move under load and are subject to wear.

Looser Bronze 66 is also suitable for worm wheels, although due to the lead content the load characteristics (c-values) are slightly lower than in Looser Bronze 65 and Looser Bronze 68. Worm wheels made of Looser Bronze 66 are preferably used for higher sliding speeds on tooth flanks at risk of mixed friction.

Chemical composition (DIN EN 1982:2017-11)

Element Cu Sn Pb Ni Zn P Fe Mn Sb S Al Si

Min. [%] 83.5 10.5 0.7 - - - - - - - -

Max. [%] 87 12.5 2.5 2 2 0,4 0,2 0,2 0,2 0,08 0,01 0.01

Mechanical properties (DIN EN 1982:2017-11)

Continuous casting-GC Centrifugal casting-GZ

Yield point Rp0,2 [N/mm2] ≥ 150 ≥ 150

Tensile strength Rm [N/mm2] ≥ 280 ≥ 280

Brinell hardness [HB] ≥ 90 ≥ 90

Elongation at fracture A [%] ≥ 5 ≥ 5

Bending fatigue strength* Rbw [N/mm2] ± 130 ± 130

Modulus of elasticity** E [kN/mm2] 90 90

* Guideline value with 108 load cycles and at 20°C / ** Guideline value

The sample bar is removed from the casting in the case of centrifugal castings and continuous castings. The sample position – e.g. lengthwise or crosswise sample – must be agreed between orderer and manufacturer: the values specified in the table apply only to wall thicknesses up to 50 mm for the blank casting. In the case of wall thicknesses over 50 mm, with the wall thickness of the blank casting being the decisive factor, it must be anticipated that the strength and hardness values are lower. This applies in particular to the yield point.

It must not be expected that the strength and hardness values are uniformly high at all points of the casting. In general, the values in the outer layers will be higher than in the core zone.

Worm-gear loading characteristics (c values)

Centrifugal casting Mould casting

Continuous operation without cooling 6.7 N/mm2 with v = 2 m/s

1.8 N/mm2 with v = 8 m/s5.4 N/mm2 with v = 2 m/s

1.6 N/mm2 with v = 4 m/s

Continuous operation with cooling 7.2 N/mm2 with v = 2 m/s

9 N/mm2 with v = 8 m/s5.8 N/mm2 with v = 2 m/s

6.7 N/mm2 with v = 4 m/s

Short duty cycle [ED] 36 N/mm2 (ED max. 5%) 27 N/mm2 (ED max. 5%)

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 18,5 Electrical conductivity [m/Wmm2] 6.2

Thermal conductivity [W/mK] 54 Specific gravity [kg/dm3] 8,7

Standards

DIN EN 1982 CuSn11Pb2-C-GS/GC/GZ DIN 1705 G/GC/GZ-CuSn12Pb

Material designation

DIN EN 1982 DIN 1705

Abbreviated designation Number Casting method Abbreviated designation Number

CuSn11Pb2-C-GS CC482K-GS GS or G G-CuSn12Pb 2.1061.01

CuSn11Pb2-C-GZ CC482K-GZ GZ GZ-CuSn12Pb 2.1061.03

CuSn11Pb2-C-GC CC482K-GC GC GC-CuSn12Pb 2.1061.04

GS = G = Sand casting; GZ = Centrifugal casting; GC = Continuous casting

Machinability

Looser Bronze 66 offers good machinability, suitable for welding and soft soldering, limited hard soldering capability.

Sliding partners

The Sliding partner should be as hard as possible and neatly ground, very finely ground or lapped for the highest loads. Spheroidal graphite iron is also a suitable shaft material. Edge pressures must be avoided.

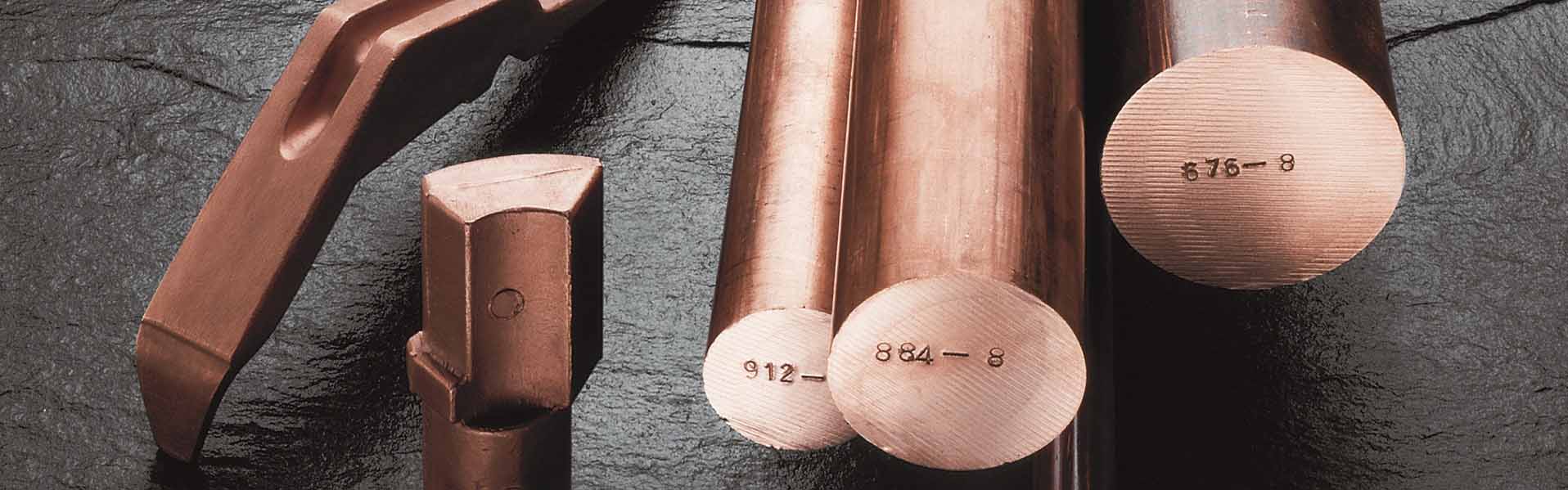

Looser Bronze 66 – Availability

- Over 130 sizes of tubular, round, flat and rectangular bars are available at short notice.

- Centrifuged rings and bushings pre-turned to the rough sizes or contour.

- Special continuous-casting production processes for hollow and solid profiles as of 1,000 kg per size.

- Ready-to-install parts in accordance with customer drawing.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.

Links

Additional information can be found in this Looser Bronzes catalog or under download.