Looser Aluminium Bronze 72 (LAB 72) – CuAl10Fe3Mn2 DIN EN 12165

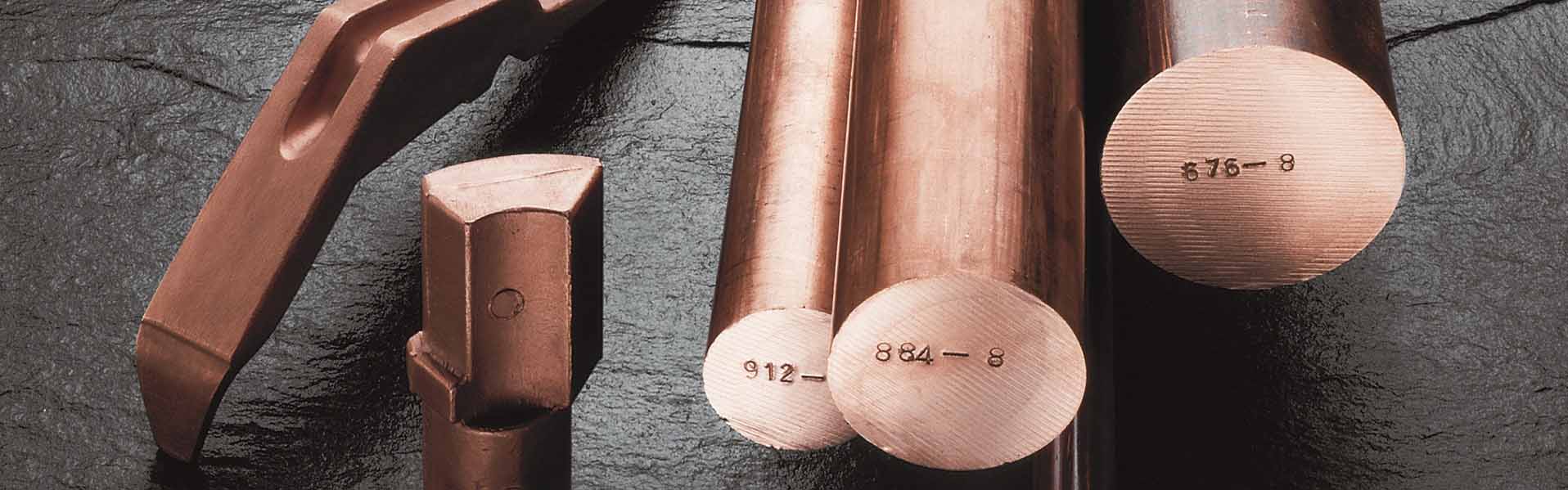

This wrought material is a copper-aluminium alloy with additions of iron and manganese, which is available at short notice in the form of round bars.

Looser Aluminium Bronze 72 is a construction material with high strength properties, even at elevated temperatures; high permanent fatigue strength; good corrosion resistance against neutral and acidic, aqueous media as well as seawater; good resistance to scaling, erosion and cavitation.

The choice of alloys is made primarily according to the required strength properties.

In the same alloy group, we stock the following wrought materials:

- Looser Aluminium Bronze 75

- Looser Aluminium Bronze 78

- Looser Aluminium Bronze 79

- Wotan Bronze AKS 59

Chemical composition (DIN EN 12165:2016-11)

Element Cu Al Fe Mn Ni Zn Si Sn Pb Other

Min. [%] - 9 2 1,5 - - - - - -

Max. [%] Rest 11 4 3,5 1 0,5 0,2 0,1 0,05 0,2

Mechanical properties (DIN EN 12165:2016-11)

Round bars Status M

Yield point Rp0,2 [N/mm2] -

Tensile strength Rm [N/mm2] -

Brinell hardness [HB] -

Elongation at fracture A [%] -

Modulus of elasticity E [kN/mm2] ~ 118

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 17 Electrical conductivity [m/Wmm2] 7

Thermal conductivity [W/mK] 59 Specific gravity [kg/dm3] 7,6

Material designation

DIN EN 12165 DIN 17665

Abbreviated designation Number Abbreviated designation Number

CuAl10Fe3Mn2 CW306G CuAl10Fe3Mn2 2.0936

Example uses

- Structural parts for chemical plant engineering.

- Scale-resistant parts; shafts, screws and bearing bushings.

Machinability

Looser Aluminium Bronze 72 can be machined like steel with the same strength. Machinability, based on CuZn39Pb3 (Ms58Pb) is approximately 30%.

Looser Aluminium Bronze 72 is well suited for forging in a temperature range of 800-950°C; this material is not very suitable for cold forming.

The annealing temperature range lies between 650-800°C; stress relief heat treatment takes place at 300-400°C. The melting point is 1045-1090°C.

Looser Aluminium Bronze 72 is well suited for protective gas and electrical resistance welding. Not suitable for soft or hard soldering or for autogenous welding.

Sliding partners

Mating steel surfaces should be hardened and finely machined. The finer the sliding surfaces, the higher the expected service life. Good lubrication is essential.

Looser Aluminium Bronze 72 – Availability

- Round bars from Ø 6–130 mm are available at short notice.

- Ready-to-install parts in accordance with customer drawing.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.

Links

Additional information can be found in this Looser Bronzes catalogue or under Téléchargement.