Looser Lead Bronze 80 (LBB 80) – CuSn7Pb15-C-GS/GC/GZ DIN EN 1982

Looser Lead Bronze 80 is a soft leaded tin bronze with particularly pronounced sliding and emergency running properties. An examination of its structure shows that the lead is evenly distributed in fine grain. It can be used as a versatile bearing material in mechanical engineering but is mainly used for bearings that are lubricated with water or petrol or where the lubrication is not always guaranteed (lack of lubrication, mixed friction).

Looser Lead Bronze 80 has good embeddability with regard to any foreign bodies possibly carried in the lubricant. Therefore, many plain bearings on machines subject to dust hazards are made from this bronze.

With effective cooling oil lubrication, the following maximum load values apply:

for centrifugal and continuous casting 50 N/mm2

for finished casting 30 N/mm2

Bearings with water lubrication and a sliding speed of up to 10 m/s can be used with a surface pressure [p] of max. 3 N/mm2.

Permitted specific surface pressure [p] of wear bearings with limited service life running in constant mixed friction: p = 15 N/mm2 at v = 0.3–1 m/s.

Hydrodynamically lubricated bearings: p up to 10 N/mm2 and a sliding speed [v] of max. 10 m/s.

Looser Lead Bronze 80 is suitable for operating temperatures up to 120°C. However, it has good resistance to many acids and alkalis, especially dilute sulphuric acid.

Chemical composition (DIN EN 1982:2017-11)

Element Cu* Pb Sn Ni Zn Sb Fe Mn S P Al Si

Min. [%] 74 13 6 0,5 - - - - - - -

Max. [%] 80 17 8 2 2 0,5 0,25 0,2 0,1 0,1 0,01 0,01

* inclusive Ni

Mechanical properties (DIN EN 1982:2017-11)

Continuous casting-GC Centrifugal casting-GZ

Yield point Rp0,2 [N/mm2] ≥ 90 ≥ 90

Tensile strength Rm [N/mm2] ≥ 200 ≥ 200

Brinell hardness [HB] ≥ 65 ≥ 65

Elongation at fracture A [%] ≥ 8 ≥ 7

Modulus of elasticity* E [kN/mm2] ≥ 75 ≥ 75

* Guideline value

The sample bar is removed from the casting in the case of centrifugal castings and continuous castings. The sample position – e.g. lengthwise or crosswise sample – must be agreed between orderer and manufacturer: the values specified in the table apply only to wall thicknesses up to 50 mm for the blank casting. In the case of wall thicknesses over 50 mm, with the wall thickness of the blank casting being the decisive factor, it must be anticipated that the strength and hardness values are lower. This applies in particular to the yield point.

It must not be expected that the strength and hardness values are uniformly high at all points of the casting. In general, the values in the outer layers will be higher than in the core zone.

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 18,8 Electrical conductivity [m/Wmm2] 7

Thermal conductivity [W/mK] 63 Specific gravity [kg/dm3] 9,1

Standards

DIN EN 1982 CuSn7Pb15-C-GS/GC/GZ VSM 10810 G-CuPb15Sn8 (G-PbBz15)

DIN 1716 G/GC/GZ-CuPb15Sn (G-SnPbBz15) ASTM Alloy C 93900

Material designation

DIN EN 1982 DIN 1716

Abbreviated designation Number Casting method Abbreviated designation Number

CuSn7Pb15-C-GS CC496K-GS GS or G G-CuPb15Sn 2.1182.01

CuSn7Pb15-C-GZ CC496K-GZ GZ GZ-CuPb15Sn 2.1182.03

CuSn7Pb15-C-GC CC496K-GC GC GC-CuPb15Sn 2.1182.04

GS = G = Sand casting; GZ = Centrifugal casting; GC = Continuous casting

Example uses

- Bearings with water lubrication, bearings for underwater pumps, centrifugal and rotary pumps, agitator bearings, bearings in exhaust fans, axle and rod bearings, bearings for locks.

- Bearings for grinding machines, milling machines, tobacco and textile machines, for the printing and paper industry, bearings for cement kilns.

- Bearings without white metal nozzle for cold rolling and foil rolling mills, for electric motors. Main bearings in machine tools, camshaft bushings.

- Acid-resistant fittings or castings.

Machinability

Looser Leaded Bronze 80 offers very good machinability. It is well suited for hard and soft soldering but not for welding.

Sliding partners

Both hardened and unhardened shafts can be used. However, shafts made of stainless steel or bronze can also be used as mating materials. Looser Leaded Bronze 80 is largely insensitive to shaft deflections that lead to strong edge pressures.

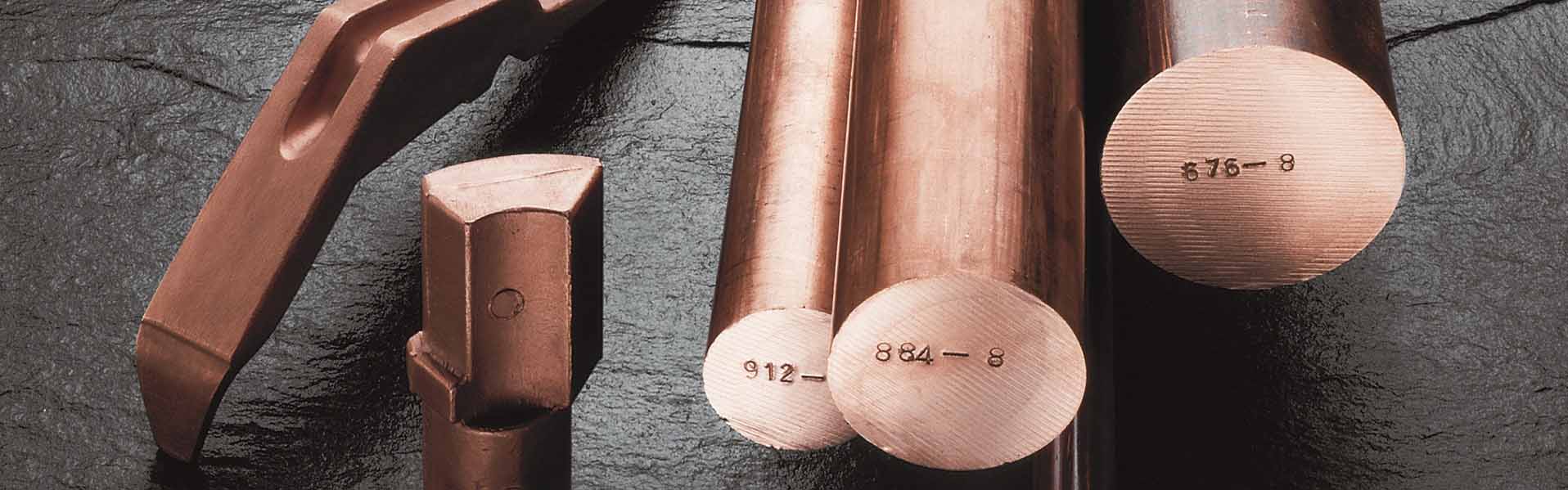

Looser Lead Bronze 80 – Availability

- Numerous sizes of tubular and round bars are available from stock or at short notice.

- Centrifuged rings and bushings pre-turned to the rough sizes or contour.

- Cut to size flat and rectangular bars bars are available at short notice.

- Special continuous-casting production processes for hollow and solid profiles as of 1,000 kg per size.

- Ready-to-install parts in accordance with customer drawing.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.