Looser Bronze 50 (LB 50) – CuSn7Zn4Pb7-C-GS/GC/GZ DIN EN 1982

Looser Bronze 50 is a medium-hard multi-material tin bronze with a dense microstructure, with good emergencyrunning properties and high wear resistance.

It is able to withstand high surface pressure and frictional pressure. Looser Bronze 50 is manufactured by centrifugal and continuous casting only. Using these state-of-the-art casting techniques gives the material a fine-grained microstructure. Looser Bronze 50 is seawater-resistant. As a bearing material, Looser Bronze 50 is superior to the sand-cast alloy GBz 14 which was long considered the best bearing bronze. Both qualities have comparable mechanical properties but the antifriction and emergency-running properties of Looser Bronze 50 are significantly better.

It has a loading capacity of up to 12 N/mm2 with hydrodynamic lubrication and sliding speeds up to v = 8 m/s.

Chemical composition (DIN EN 1982:2017-11)

Element Cu* Sn Pb Zn Ni Sb Fe P S Al Si

Min. [%] 81 5,2 5 2 - - - - - - -

Max. [%] 86 8 8 5 2 0,3 0,2 0,1 0,1 0,01 0,01

* inclusive Ni

Mechanical properties (DIN EN 1982:2017-11)

Continuous casting-GC Centrifugal casting-GZ

Yield point Rp0,2 [N/mm2] ≥ 120 ≥ 120

Tensile strength Rm [N/mm2] ≥ 260 ≥ 260

Brinell hardness [HB] ≥ 70 ≥ 70

Elongation at fracture A [%] ≥ 12 ≥ 12

Bending fatigue strength* Rbw [N/mm2] ± 110 ± 110

Modulus of elasticity** E [kN/mm2] ≥ 98 ≥ 98

* Guideline value with 108 load cycles and at 20°C / ** Guideline value

The sample bar is removed from the casting in the case of centrifugal castings and continuous castings. The sample position – e.g. lengthwise or crosswise sample – must be agreed between orderer and manufacturer: the values specified in the table apply only to wall thicknesses up to 50 mm for the blank casting. In the case of wall thicknesses over 50 mm, with the wall thickness of the blank casting being the decisive factor, it must be anticipated that the strength and hardness values are lower. This applies in particular to the yield point.

It must not be expected that the strength and hardness values are uniformly high at all points of the casting. In general, the values in the outer layers will be higher than in the core zone.

Physical properties (Guideline values)

Coefficient of thermal expansion [10-6/K] 18,5 Electrical conductivity [m/Wmm2] 7,5

Thermal conductivity [W/mK] 64 Specific gravity [kg/dm3] 8,8

Standards

DIN EN 1982 CuSn7Zn4Pb7-C-GS/GC/GZ AFNOR UE7Z5Pb6

DIN 1705 G/GC/GZ-CuSn7ZnPb (Rg7) ASTM Alloy C 93200

VSM 10810 G-CuSn7Pb6Zn4 (Rg7) SAE CA 932 B (660)

Material designation

DIN EN 1982 DIN 1705

Abbreviated designation Number Casting method Abbreviated designation Number

CuSn7Zn4Pb7-C-GS CC493K-GS GS or G G-CuSn7ZnPb 2.1090.01

CuSn7Zn4Pb7-C-GZ CC493K-GZ GZ GZ-CuSn7ZnPb 2.1090.03

CuSn7Zn4Pb7-C-GC CC493K-GC GC GC-CuSn7ZnPb 2.1090.04

GS = G = Sand casting; GZ = Centrifugal casting; GC = Continuous casting

Example uses

- Plain bearing bushes subject to normal loading and high loading with liquid friction in the field of general machine construction and apparatus engineering (load peaks of p up to 40 N/mm2 permitted), bearings subject to temporary lubricant deficiency and limited service life; bearings used in the field of crane and excavator construction, bearings for conveyor systems, bearings for agricultural and construction machinery, for textile and packaging machines and for electric motors and transmissions.

- Main-spindle bearings and sub-spindle bearings in machine-tool construction, crank bearings and toggle-lever bearings with load peaks of p up to 30 N/mm2 with adequate lubrication.

- Guide bushings, print rollers, thrust bearings, pump cylinders, seal rings; cylinder guide rings, base bushing liners and stuffing-box liners for hydraulic presses. Moderately loaded coupling pieces and slip rings. Moderately to highly loaded sliding strips and adjusting strips.

- Worm gears subject to low load at high sliding speeds (v up to 8 m/s), but low duty factor (up to 5% ED). We recommend the following for gears subject to high load Looser Bronze 65, Looser Aluminium Bronze 75 or Wotan Bronze AKS 59.

Machinability

Looser Bronze 50 can be machined very well with short chipping. It cannot be welded well, can be soldered well and can conditionally be brazed.

Sliding partners

Unhardened structural steel can be used as sliding partner provided lubrication is good; however, preference should be given to hardened shafts at high sliding speeds and with higher loading. Looser Bronze 50 can also be used when subject to slight edge pressure.

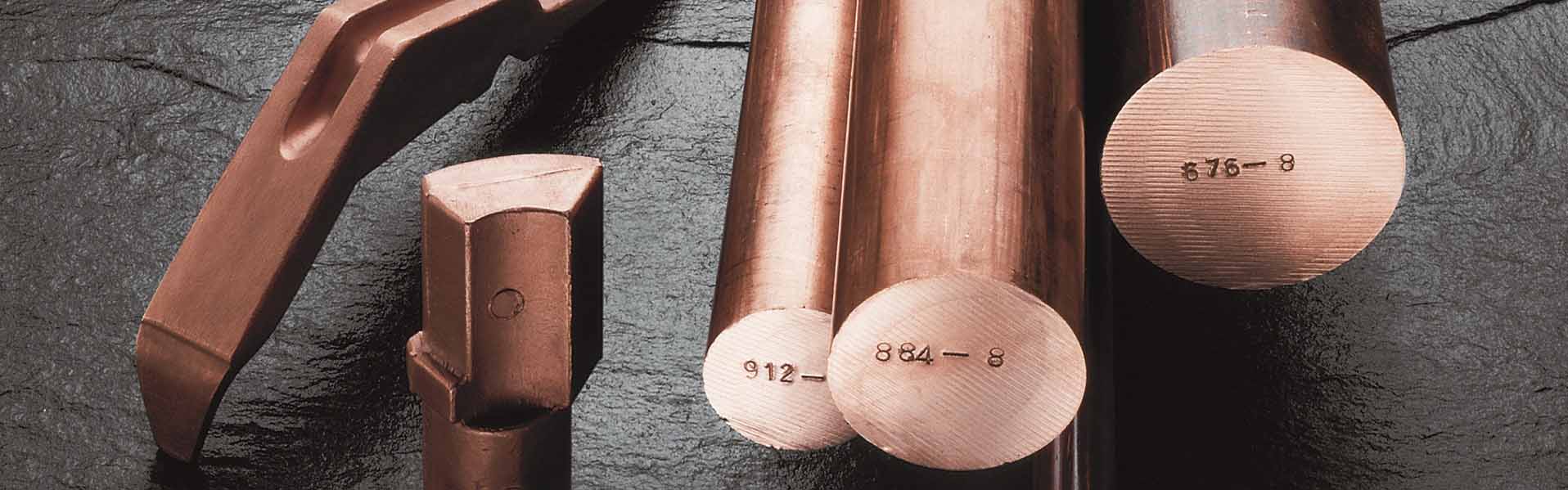

Looser Bronze 50 – Availability

- Over 700 sizes of tubular, round, flat, rectangular and hexagonal bars.

- Additional sizes – specifically edge profiles – are available at short notice.

- Ground bars – pointed and chamfered – from Ø8 h8 to 50 h8 for lathing (décolletage).

- Centrifuged rings and bushings pre-turned to the rough sizes or contour.

- Edge profiles sawn to the required sizes from baseplates.

- Special continuous-casting production processes for hollow and solid profiles as of 1,000 kg per size.

- Ready-to-install parts in accordance with customer drawing.

We will be more than pleased to advise you.

Subject to technical modifications; no responsibility is accepted for the accuracy of this information.