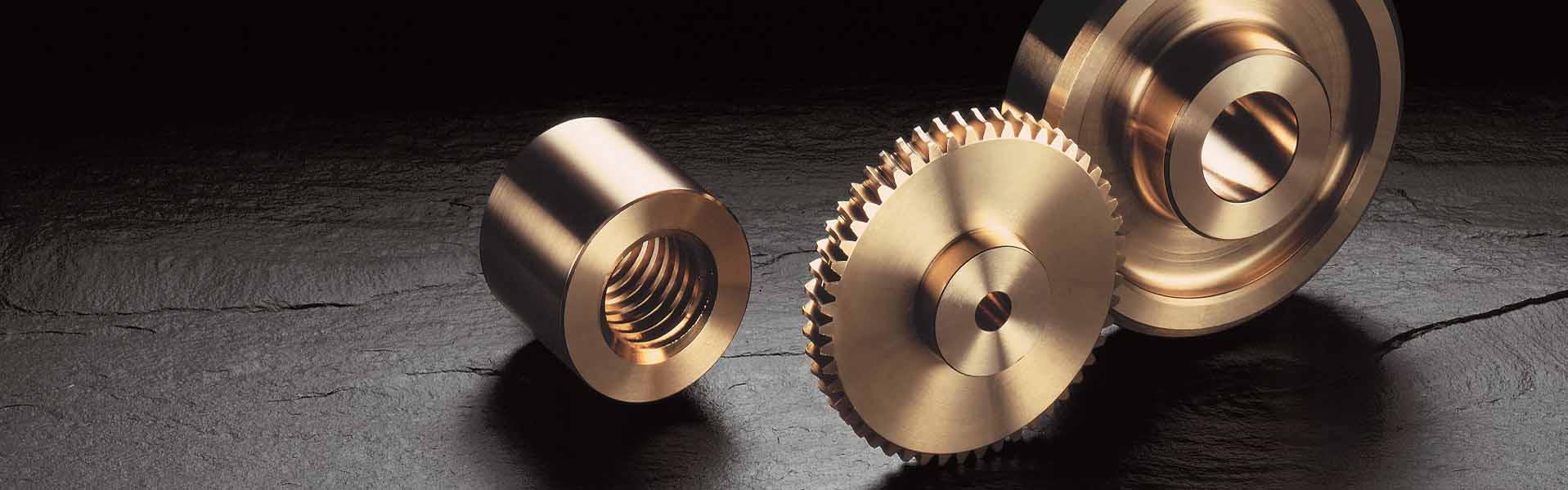

When designing a machine or plant, the designer is continually confronted with the question as to which bronze is best for their application.

It is often possible to draw on accumulated experience. But if this is not the case, in this article we would like to show you how to approach the evaluation of a suitable plain bearing material.

Plain bearings or sliding elements often have an important function in a machine, plant or device.

For this reason, careful assessment, possibly in conjunction with a specialist, is of crucial importance for a successful project.

When the bearing material, oil viscosity and bearing clearance are correctly selected, a bronze bearing has the following advantages:

- Plain bearings are capable of damping vibrations, have a relatively low noise level and are easy to install

- A high degree of concentricity accuracy, vibration-free operation and therefore the ideal machine element for all precision machines.

- Friction bearings require little space and are adaptable in design

- Plain bearings are more cost-effective than roller bearings, particularly in larger dimensions

- Plain bearings are largely unaffected by corrosion and are therefore also suitable for machines operating in a humid atmosphere or under tropical conditions

- When correctly designed, plain bearings can be deployed up to the highest running speeds.

The following design data and supplementary information will be helpful for determining an ideal bronze material:

Design data Supplementary information

1. Mass of the plain bearing [mm] 6. Shaft material (hardness, surface finish)

2. Load on the bearing [N] 7. Load characteristics (uniform, alternating, jerky, oscillating)

3. Rotational speed [min-1] or running speed [m/s] 8. External influences (e.g. humidity, dust, sand, acids, fumes)

4. Lubricant [ISO VG] 9. Permissible bearing temperature [°C]

5. Ambient temperature [°C] 10. Regulations (for example RoHS, REACH)

In a first step, from this design data it is possible to determine the specific bearing load, which is one of the most important criteria for the selection of a bronze material.

Example:

Load on the bearing [F]: 15000 N

Diameter [d]: 20 mm

Width [b]: 30 mm

specific bearing load = 25 N/mm2

As a rule of thumb, we recommend that for a static condition, the specific bearing load should not exceed one-third of the yield point. Thus, for the Looser Bronze 50, this is 40 N/mm2 (see following table). Under dynamic load, the permissible bearing load can quickly reach 20 N/mm2 or less, depending on the speed.

The previously mentioned yield point is of central importance for the design of a plain bearing. The following table of selected alloys provides an overview:

Looser designation Number Yield point Rp0,2 [N/mm2] Recommended mating material

Looser Lead Bronze 80

CC496K ≥ 90 unhardened steel

Looser Bronze 50 CC493K ≥ 120 unhardened steel

Looser Bronze 65 CC483K ≥ 150 hardened and ground steel

Looser Bronze 68 CC484K ≥ 180 hardened and ground steel

Caro Bronze CC459K ≥ 280 hardened and ground steel

Looser Aluminium Bronze 75 CW307G ≥ 300 hardened and ground steel

Looser Aluminium Bronze 79 - ≥ 600 hardened and ground steel

The semi-finished range of Walter Looser AG is divided into the following groups:

- Multi-material tin bronzes and tin bronzes

- Aluminium bronzes

- Leaded bronzes

- Special brasses

- Low-alloy wrought copper alloys

When selecting a bronze material for a plain bearing, if the load is not too high, we recommend starting by testing our main alloy, Looser Bronze 50. With this alloy you will find the largest range of dimensions. In the Looser Bronze 50 range we also offer ground round bars with h8 tolerance from diameter 8-50 Ø.

Lubrication is an essential influence on the service life of a plain bearing pairing. Usually oil or grease is used. If the plain bearing runs in water, for example, then our Looser Lead Bronze 80 could be used. However, lubrication can also be provided by a solid lubricant (e.g. graphite).

In our material data sheets the term “emergency running characteristics” frequently appears. By this we mean how long a plain bearing can continue to function with a short-term lack or failure of lubricant without being damaged.

10 Examples of practical applications:

- Looser Bronze 50 is often used for general bearings or sliding elements in general mechanical engineering. In this alloy we also offer a standard range with the Looser LG 41 bearing.

- For V-threads, fine-pitch or trapezoidal threads, the Looser Bronze 50 has proven itself very well in practice.

- Looser Bronze 68 or the Looser Aluminium Bronze 75 are often deployed for gear wheels with enhanced flexural fatigue strength requirements.

- Our Looser Aluminium Bronze 75 is often purchased for applications with high dry friction, (e.g. pressure plates, worm gears, gear wheels or chain guides).

- Where there are enhanced requirements for electrical or thermal conductivity, low-alloyed copper alloys are often used, e.g. Lobrodur 18.

- Undesirable edge loading in a plain bearing can massively reduce the service life or cause bearing damage. Softer alloys such as Looser Lead Bronze 80 or Looser Bronze 50 have often proved themselves in practice.

- Our Caro Bronze is suitable for thin-walled plain bearings under higher loads and hardened shafts.

- Where it is particularly important for a tempered aluminium multi-alloy bronze to have a guaranteed higher breaking strain, then our Wotan Bronze AKS 59 may be of interest.

- The low-alloy copper alloy, Lobrodur 18, is often used for guide bushings, including valve guide bushings. This material also has good cold forming and excellent hot forming properties.

- Rolled sheets or their blanks for larger sliding plates are available at short notice in Looser Aluminium Bronze 75 and Looser Phosphor Bronze CuSn6.

Further examples of applications can be found in our individual material data sheets.

Additional information:

- Another important point is the availability of the selected material in the required dimensions. Despite our wide and deep range of stock, not every dimension is available in every size.

- It is quite possible that an application achieves equally good results with, for example, a bronze or special brass. Furthermore, the effects of bronzes with high tensile strength must be taken into account. The higher the mechanical properties of a bronze material, the worse the anti-friction and emergency running properties.

- There are countless applications for bronze materials, in this article we can only offer a small insight into this exciting field.

At Walter Looser AG you will find a capable team who can advise you on all aspects in the field of bronzes and plain bearings, by phone, email or on site.

We will be more than pleased to advise you.

Information about the author: Daniel Böhler

The author graduated as a mechanical engineer and has completed postgraduate studies in Industrial Engineering with Business Studies. He joined Walter Looser AG. after working for several years on the design and development of punching machines. Daniel Böhler is responsible for sales, marketing and technology.